Principle of light guide plate

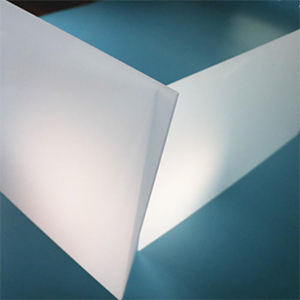

LCD light guide plate lighting technology was first invented by Japan mingtuo company in 1986, known as edge light, which is the mainstream method of notebook computer LCD backlight lighting. Its working principle is that the pure white light emitted by the cold cathode fluorescent tube (line light source) is introduced from the end face of the transparent plate and diffused to the whole board surface by using the PMMA transparent light guide plate. When the light reaches the white reflection point printed on the back of the light guide plate, diffuse reflection occurs and emits from the plate surface (working surface) perpendicular to the light source input surface.

By skillfully using the principle of total reflection of light on the interface of transparent plate, the light emitted from the end face is deflected by 90 ° and emitted from the front, so as to play the role of lighting. Because of its high surface brightness, compact size and high efficiency of light utilization, this lighting method has been widely used in notebook computers and digital cameras, which need to use large area LCD.

The key of LCD light guide plate lighting technology is the total reflection effect of light in PMMA. We know that when light passes through two kinds of transparent media, it will reflect and refract. When light shoots into the air from a transparent medium with a refractive index greater than air, due to the different refractive index, when the incident angle θ is greater than a certain angle, the total reflection will occur at the interface, and no light will be emitted from the medium. In other words, the transmission loss of light in the medium only depends on the absorption of light by the medium, However, there is no loss when reflecting on the interface (the reflection of light on the metal surface usually loses 10% - 15%). In conclusion, this is exactly the characteristic of PMMA light guide plate.

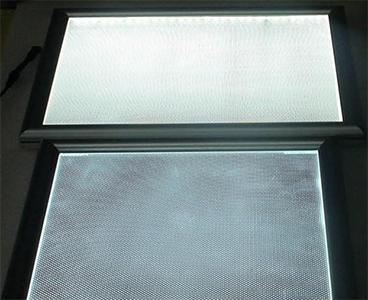

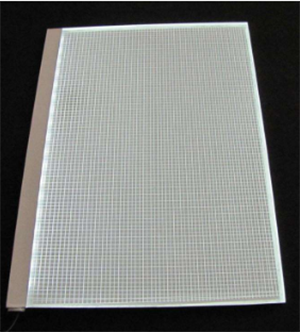

In order to export the total reflected light in PMMA light guide plate from the working face of light guide plate, it is necessary to form a reflective layer on the back of the light guide plate (opposite to the working face) to scatter the light, so that the working face can obtain a certain brightness of uniform light output. The back of the light guide plate is screen printed to form reflective dot instead of full back (see Fig. 3), so as to ensure that far away from the light source, the brightness will not be insufficient due to excessive attenuation of light. The printing ink is composed of titanium dioxide (TiO2) and barium sulfate (BaSO4) mixed acrylic binder. The refractive index of TiO 2 crystal to visible light is as high as 2.62. It reflects and refracts the light from the PMMA light guide plate to the light guide plate and outputs from the working surface, so it has a strong reflection effect.

What are the advantages of light guide plate?

What are the main types of light guide plate?

1. By shape

Plate: the light guide plate is rectangular from the light inlet.

Wedge plate: also known as inclined plate, from the light into the point for one side is thick, the other side is thin into wedge (triangle) shape.

2. By outlets

Printing: after the light guide plate has finished the shape processing, the dot will be printed on the reflecting surface by printing, which can be divided into IR and UV.

Non printing: the dot is directly formed on the reflecting surface when the light guide plate is formed. It can be divided into chemical etching, V-CUT, stamper and internal diffusion.

3. By the light input

Side entry light type: the luminous body (lamp or LED) is placed on the side of the light guide plate.

Straight down type: the luminous body (lamp or LED) is placed under the light guide plate.

4. Press forming

Injection molding: the optical grade PMMA particles are cooled and formed by injection molding machine

Cutting forming: the optical grade PMMA plate is finished by cutting process.

online service

online service 0086-591-8806 9579

0086-591-8806 9579 88067049

88067049 izzy@lexinda.com

izzy@lexinda.com sarahlpr

sarahlpr 86-15336506363

86-15336506363